Why Local Partnership Matters in Plastic Welding Equipment

India's plastic welding and fabrication industry operates under fundamentally different conditions than European and Western markets. Understanding these differences—and having a partner who can navigate them effectively—often determines the success or failure of your equipment investment.

The Indian Industrial Reality: Tougher Conditions, Different Challenges

When international manufacturers design plastic welding equipment, they typically optimize for European operating conditions: moderate temperatures, clean environments, stable power supply, and highly trained operators. While these machines represent excellent engineering, they face very different realities in Indian industrial settings.

Operating Environment Challenges

Temperature Extremes: Indian fabrication facilities and field installation sites regularly experience temperatures exceeding 40°C during summer months. This heat stress affects equipment performance, accelerates component wear, and creates challenges for temperature-sensitive welding processes.

Dust and Particulate Contamination: Many Indian industrial environments have higher dust levels than European facilities. Airborne particulates can infiltrate equipment, affecting motors, electronics, and precision components.

Humidity Variations: Monsoon seasons bring extreme humidity that can impact electrical systems, create corrosion issues, and affect material storage conditions.

Power Supply Instability: While improving, many Indian industrial areas still experience voltage fluctuations, power surges, and occasional outages that can damage sensitive electronic equipment without proper protection.

These aren't minor considerations—they directly impact equipment reliability, maintenance requirements, and operational lifespan.

Operator Skill and Training Realities

European markets typically have well-established vocational training systems producing operators with standardized welding qualifications. India's situation is different.

Knowledge Gaps: Many operators enter plastic welding without formal training in thermoplastic materials, welding theory, or equipment operation. They learn on the job, which can lead to improper techniques, equipment misuse, and inconsistent quality.

Training Infrastructure: While improving, India still lacks widespread specialized training programs for plastic welding technologies, creating a skilled labor shortage in this growing sector.

This skills gap means that equipment suppliers who provide comprehensive training and ongoing technical support deliver dramatically more value than those who simply deliver machines and walk away.

Growth Sectors Driving Plastic Welding Demand in India

Despite these challenges—or perhaps because of them—India's plastic welding industry is experiencing significant growth across multiple sectors.

Key Growth Industries

Water and Wastewater Treatment: Expanding municipal infrastructure and industrial effluent treatment requirements are driving massive demand for plastic piping, tanks, and containment systems. Plastic's corrosion resistance makes it ideal for these applications.

Infrastructure Development: Roads, bridges, buildings, and civil engineering projects increasingly incorporate plastic components for drainage, waterproofing, and protective systems.

Metal and Metalworking Industries: Surface treatment facilities, electroplating operations, and metal processing plants require corrosion-resistant plastic fabrication for chemical handling and containment.

Solar Energy: India's ambitious solar capacity expansion requires specialized mounting systems, cable management, and protective enclosures where plastic fabrication plays important roles.

Semiconductor Manufacturing: As India develops semiconductor fabrication capabilities, cleanroom-compatible plastic components and chemical handling systems become essential.

Chemical and Pharmaceutical: Process industries require chemical-resistant tanks, piping, ventilation systems, and containment—all areas where plastic welding technology excels.

This diverse growth across multiple sectors creates opportunities for fabricators equipped with proper technology and expertise.

The Hidden Cost of Equipment Downtime

One reality that many fabricators underestimate until they experience it firsthand: the true cost of equipment failure.

Production Loss Economics

When a critical welding machine goes down, the immediate cost isn't just the repair—it's the production capacity lost while equipment sits idle.

Consider a typical scenario: a sheet welding machine fails on a large fabrication project. The direct costs cascade quickly:

Labor crews sitting idle or reassigned to less critical work

Project timelines extending, potentially triggering penalty clauses

Customer relationships strained by delayed deliveries

Opportunity cost of projects you cannot bid on while capacity is limited

In many cases, the production value lost in a single day of downtime exceeds the original cost of the equipment itself.

This economic reality makes service response time and parts availability not just convenience factors—they're business-critical concerns.

Durel's Service Infrastructure: Built for Indian Realities

Understanding these challenges, Durel has built a service infrastructure specifically designed to minimize downtime and keep fabricators productive.

Rapid Service Turnaround

24-Hour Service Commitment: Within 24 hours of equipment reaching any of our service centers, we can diagnose problems, complete repairs, and dispatch equipment back to you. This isn't an aspiration—it's a standard commitment backed by proper staffing and processes.

Critical Spare Parts Inventory: We maintain stock of essential components at our service centers across India. When a common wear part fails, you're not waiting weeks for international shipping—replacement parts are available immediately.

Multi-Location Service Network: With service capabilities in Chennai, Mumbai, Delhi, Ahmedabad, and Bhopal, you're never far from expert technical support regardless of where your operations are located.

Preventive Maintenance Programs: We help customers implement maintenance schedules that catch potential problems before they cause failures, dramatically reducing unexpected downtime.

Technical Expertise That Understands Indian Conditions

Our service technicians aren't just following repair manuals—they understand how equipment performs in Indian operating conditions. They've seen the specific failure patterns that result from dust, heat, power fluctuations, and operating intensity unique to Indian facilities.

This experience means faster, more accurate diagnosis and solutions that address root causes rather than just symptoms.

The Costly Mistake of Buying Without Local Support

The appeal of direct imports or working with suppliers lacking service infrastructure is understandable—initial purchase prices may be lower. But this apparent savings often proves expensive in ways that aren't obvious until problems emerge.

Real-World Example: The Value of Local Expertise

Consider the experience of one fabricator (we'll call them Customer X) who purchased a sheet welding machine directly from a Chinese manufacturer to save costs.

The equipment arrived, but despite multiple calls with the manufacturer, the customer couldn't get the machine commissioned and operational. Language barriers, time zone differences, and lack of on-site support created a frustrating situation with expensive equipment sitting unused.

Durel engineers stepped in, assessed the installation, and successfully commissioned the machine. The customer immediately understood the value of competent local support.

Subsequently, this fabricator switched their equipment procurement strategy entirely, purchasing a CNC router, four extrusion welders, and multiple hot air guns through Durel. The initial savings attempt on one machine cost them far more in downtime and frustration than the price difference would have been.

Supporting Legacy Equipment

Durel's commitment to customer support extends beyond equipment we sold originally. We service machines that customers purchased from European manufacturers years—even decades—before Durel International was established.

Some customers still operate equipment purchased 20+ years ago, and Durel continues supporting these machines to ensure they remain productive. This long-term service commitment reflects our understanding that fabricators need partners who are there for the entire equipment lifecycle, not just the initial sale.

Why Local Partnership Delivers Competitive Advantage

In India's increasingly competitive fabrication market, operational reliability becomes a differentiator. Companies that minimize downtime, maintain consistent quality, and respond quickly to opportunities gain market share.

The Partnership Advantage

Rapid Problem Resolution: When equipment issues arise, having local technical support means problems get solved in hours or days, not weeks or months.

Application Engineering Support: New projects or unfamiliar materials? Local experts can provide guidance, recommend settings, and help troubleshoot quality issues without language barriers or time delays.

Training Investment: Suppliers with local presence can provide hands-on training that builds your team's capabilities—not just basic operation, but optimal techniques and preventive maintenance.

Parts Availability: Critical spare parts in stock locally mean repairs happen quickly, not after extended waits for international shipping and customs clearance.

Continuous Improvement: Ongoing relationships with local technical experts help you continuously optimize processes, adopt new techniques, and stay current with industry developments.

Cost of Ownership vs. Purchase Price

When evaluating equipment suppliers, fabricators often focus heavily on initial purchase price. While understandable, this perspective misses the larger economic picture.

Total cost of ownership includes:

Initial equipment purchase

Installation and commissioning

Operator training

Ongoing maintenance and consumables

Repair parts and service

Downtime costs when equipment fails

Technical support for application challenges

Equipment lifecycle and replacement timing

Durel's approach emphasizes cost of ownership rather than just purchase price. We help customers understand how equipment investment performs economically over its entire service life and whether that ROI meets business requirements.

Sometimes this means recommending higher initial investment in equipment that delivers better reliability, lower maintenance costs, and longer productive life. Other times it means right-sizing equipment to actual needs rather than overselling capacity you won't use.

This honest assessment of cost economics builds long-term relationships based on mutual success rather than transactional sales.

The Credibility Factor: Global Brands in Indian Markets

There's another strategic advantage to working with established international brands through local partners like Durel: credibility.

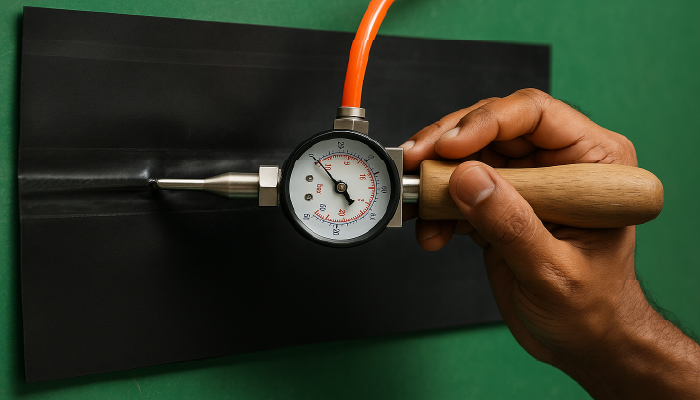

When your fabrication facility operates Ritmo welding equipment, Buckleys testing instruments, and other globally recognized brands, you signal professional capability to your customers. They understand you're serious about quality, invested in proper tooling, and capable of delivering internationally competitive work.

This credibility often translates directly into winning better projects and commanding premium pricing for your fabrication services.

Moving Forward: Choosing the Right Partner

India's plastic welding and fabrication industry will continue growing as infrastructure development accelerates, environmental regulations drive adoption of corrosion-resistant materials, and manufacturing sectors expand.

Fabricators who thrive in this growth will be those with reliable equipment, skilled operators, responsive service support, and expert guidance when tackling new applications.

The choice isn't really about equipment brands or specifications—it's about choosing a partner who understands Indian operating realities, provides comprehensive support, and is genuinely invested in your long-term success.

Durel International has built our entire business model around being exactly this partner.

Experience the difference that comprehensive local support makes for your plastic welding and fabrication operations.

Contact Durel International to discuss how our nationwide service infrastructure, technical expertise, and commitment to customer success can support your business growth.

Local expertise. Global standards. Your success.