The ROI of Proper Plastic Welding Education

In plastic fabrication and welding, the quality of your equipment matters. But equipment performance is only as good as the operators using it. Proper training transforms expensive machinery into productive assets that deliver consistent quality, while untrained operation turns even premium equipment into sources of defects, downtime, and danger.

The Hidden Costs of Untrained Operators

Many fabricators view operator training as an optional expense or one-time event during equipment commissioning. This perspective overlooks the substantial costs that untrained or poorly trained operators create daily.

Five Critical Problems from Inadequate Training

1. Improper Welds and Quality Failures

Untrained operators produce inconsistent welds with poor fusion, inadequate strength, and aesthetic defects. These quality issues manifest as:

Customer rejections and project rework

Material waste from scrapped components

Reputation damage when defective work reaches end users

Lost bids when word spreads about quality inconsistency

2. Human Safety Risks

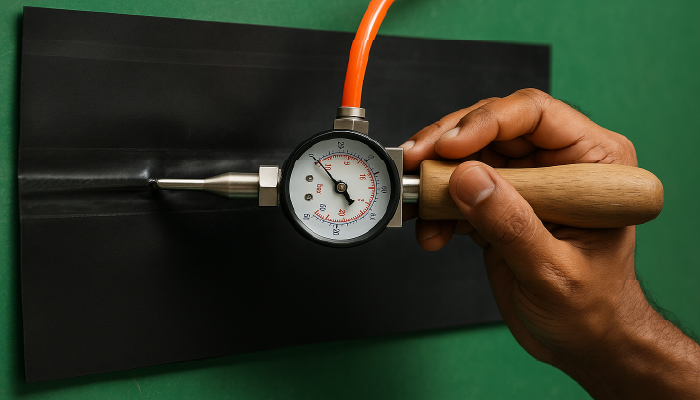

Plastic welding equipment operates at high temperatures and involves electrical systems, pressurized components, and moving parts. Operators who don't understand proper safety protocols risk burns, electrical shock, pinch injuries, and exposure to fumes.

Beyond the human cost of workplace injuries, safety incidents create regulatory complications, insurance impacts, and operational disruptions.

3. Premature Equipment Failure

One of the most expensive consequences of poor training is equipment damage from improper operation. A common example: heating element failure in welding equipment.

Many operators don't understand that heating elements require proper cooling cycles before shutdown. Turning equipment off while heating elements are still at peak temperature drastically shortens their service life, leading to expensive repairs and unexpected downtime.

This single training point—proper cooling procedures—can extend heating element life by years and prevent failures that cost thousands in parts and lost production time.

4. Productivity Loss

Untrained operators work slower, make more mistakes that require correction, and don't understand optimal techniques for different materials and applications. The productivity difference between trained and untrained operators often exceeds 50% for the same equipment and tasks.

When you calculate hourly labor costs multiplied by the productivity gap across weeks and months, the lost value becomes substantial.

5. Poor Finished Product Appearance

Professional fabrication requires not just functional welds but clean, attractive finished products. Untrained operators produce work with burn marks, rough surfaces, visible defects, and inconsistent appearance.

Even when these cosmetic issues don't affect structural performance, they impact customer perception, product value, and your ability to command premium pricing.

The Most Expensive Training Gap: Butt Fusion Welding

Among various plastic welding technologies, butt fusion welding is particularly sensitive to operator skill—and mistakes here carry especially high costs.

The Cooling Time Critical Point

In butt fusion welding, proper cooling time is essential for achieving full weld strength. The joint must cool under maintained pressure for a specified duration based on pipe diameter and material type.

What happens when operators don't understand this:

Insufficient cooling time produces welds that initially appear fine but lack proper fusion strength. These weak joints may pass visual inspection but fail under pressure or stress.

In buried pipeline applications—common for water, gas, and chemical distribution—discovering these failures requires excavation to expose the failed joint, replacement of the defective section, proper re-welding, backfilling, and often dealing with contamination or service disruption.

The excavation, repair, and restoration costs can easily run 20 times the original cost of making the weld correctly.

When you understand this economic reality, the value of proper training becomes crystal clear. Spending on training to prevent even a single field failure delivers exceptional return on investment.

Durel's Comprehensive Training Approach

At Durel International, we've witnessed firsthand how proper training transforms operator capability and business results. Our training programs are designed to build genuine competence, not just check boxes.

Training Program Components

Theory Foundation: Understanding why techniques work, not just how to perform them. This includes material science basics, welding process fundamentals, and quality factors.

Hands-On Practice: Supervised practical training where operators develop muscle memory and technique under expert guidance, with immediate feedback on their work.

Certification: Formal recognition of competency that validates operator skills to customers and provides operators professional credibility.

Equipment-Specific Training: Detailed instruction on the specific machines operators will use, including proper settings, maintenance procedures, and troubleshooting common issues.

Beyond Basic Operation: Service Training

Durel goes further than most equipment suppliers by training customers not just on equipment operation, but also on how to perform routine maintenance and service tasks themselves.

This empowers fabricators to handle minor repairs, conduct preventive maintenance, and minimize reliance on external service calls for routine items. The time and cost savings from this capability add up significantly over equipment life.

Equipment Sensitivity to Operator Skill

While all plastic welding benefits from trained operators, certain technologies are particularly sensitive to operator technique and knowledge.

Extrusion Welding: Where Training Matters Most

Extrusion welding represents one of the most operator-dependent plastic welding processes. Unlike automated butt fusion or electrofusion machines with preset cycles, extrusion welding requires continuous operator control of:

Travel speed along the weld path

Angle and pressure of the welding shoe

Coordination of filler material feed

Temperature adjustment for varying conditions

Recognition of proper fusion appearance

An experienced, well-trained extrusion welder produces strong, clean welds efficiently. An untrained operator struggles with consistency, creates defects, wastes material, and works slowly.

The quality and productivity gap between trained and untrained extrusion welders is dramatic—often the difference between profitable operations and money-losing projects.

Quality Improvement from Training Investment

While specific percentage improvements vary by application and starting skill level, the quality benefits of proper training are consistently significant.

Organizations that implement comprehensive training programs report:

Dramatic reduction in weld defects and customer rejections

Improved first-time quality rates

Fewer warranty claims and field failures

Enhanced customer satisfaction and repeat business

Ability to take on more complex, higher-value projects

The quality improvement isn't just about reducing bad outcomes—it's about enabling work you couldn't reliably produce before training. This capability expansion often opens new market opportunities and customer relationships.

Addressing India's Skilled Labor Shortage

India's plastic welding industry faces a recognized challenge: insufficient supply of trained welding technicians relative to growing demand.

Traditional vocational training infrastructure hasn't kept pace with industry growth, creating a skills gap that limits fabricators' ability to expand operations and take advantage of market opportunities.

Durel actively works to address this shortage through comprehensive training programs that develop operator capability rather than relying on already-scarce trained personnel.

Building Internal Capability

Rather than competing for limited trained operators, forward-thinking fabricators invest in training programs that develop skills within their existing workforce. This approach:

Creates loyalty among employees who receive valuable skill development

Builds institutional knowledge specific to your applications and materials

Reduces dependence on external labor markets

Provides competitive advantage through superior workforce capability

Ongoing Training: Not a One-Time Event

Effective training isn't just initial equipment orientation when machinery arrives. It's an ongoing process that evolves with your business needs.

Continuous Skill Development

Refresher Training: Periodic updates ensure operators maintain best practices and don't develop bad habits over time.

New Application Training: When taking on different materials, unfamiliar welding processes, or new customer requirements, targeted training accelerates capability development.

Advanced Technique Training: Helping experienced operators refine skills and learn optimization approaches for improved efficiency and quality.

Cross-Training Programs: Developing versatility so operators can handle multiple equipment types and welding processes, providing operational flexibility.

Durel supports customers throughout this ongoing training journey, not just at initial equipment delivery.

Calculating Training ROI

When considering training investment, calculate the real financial impact across multiple factors:

Defect Reduction Value: How much do rejections, rework, and warranty claims currently cost? Training typically reduces these expenses dramatically.

Productivity Improvement: If training increases output per operator by even 20-30%, how does that improved efficiency translate to revenue capacity or reduced labor costs?

Equipment Life Extension: Preventing premature failures through proper operation extends equipment life and reduces capital replacement frequency.

Safety Incident Avoidance: Workplace injuries carry direct costs (medical, compensation, regulatory) and indirect costs (productivity loss, insurance impacts, morale effects).

Market Opportunity Expansion: Can you bid on projects requiring certified operators or quality standards you couldn't previously meet?

When you calculate across these dimensions, comprehensive training programs typically deliver ROI measured in months, not years.

Safety: The Non-Negotiable Training Component

Beyond quality and efficiency, safety training protects your most valuable asset—your people.

Plastic welding involves inherent hazards: high temperatures, electrical systems, pressurized equipment, and sometimes toxic fumes depending on materials. Proper training ensures operators understand:

Personal protective equipment requirements

Safe equipment operation procedures

Emergency shutdown protocols

Proper ventilation and fume management

Electrical safety practices

Material handling and storage safety

Safety incidents don't just harm individuals—they disrupt operations, damage company reputation, create regulatory complications, and impact insurance costs. Comprehensive safety training is essential risk management.

Making Training Investment a Priority

In competitive markets with pressure on project margins, training expenses sometimes get deferred or minimized. This short-term thinking creates long-term costs that far exceed training investment.

The Training Decision

Consider two fabrication companies with identical equipment:

Company A invests in comprehensive initial training, periodic refresher programs, and advanced technique development. Operators produce consistent quality, equipment runs reliably, and the company builds a reputation for professional work.

Company B minimizes training investment, focusing only on basic operation. Operators struggle with consistency, equipment experiences premature failures, and the company competes primarily on price because quality reputation is weak.

Over time, Company A wins better projects, commands premium pricing, experiences lower costs from reduced rework and equipment problems, and attracts skilled employees who value professional development opportunities.

Company B remains stuck in price-competitive commodity work with thin margins and high stress.

The difference between these trajectories? Training investment that builds genuine capability.

Durel's Partnership in Workforce Development

At Durel International, we view training as a core part of our value proposition, not an afterthought or optional service.

When you invest in equipment through Durel, you're also investing in workforce capability development that makes that equipment productive. Our training programs are designed by professionals with 25 years of plastic welding industry experience who understand not just equipment operation, but the real-world challenges fabricators face daily.

We're invested in your success—which means we're invested in your team's capability to deliver exceptional work consistently.

Ready to transform your team's plastic welding capability?

Contact Durel International to discuss training programs that build the skills your business needs for quality, efficiency, and competitive advantage.

Skilled operators. Quality results. Competitive advantage.