Why Spark Testing is Essential for Coating Quality Control in India

When it comes to protective coatings and pipeline linings, invisible defects can lead to catastrophic failures. Spark testing technology offers a proven solution for coating inspection and pinhole detection—yet many Indian industries have yet to adopt this critical quality control method.

Understanding Spark Testing for Coating Defect Detection

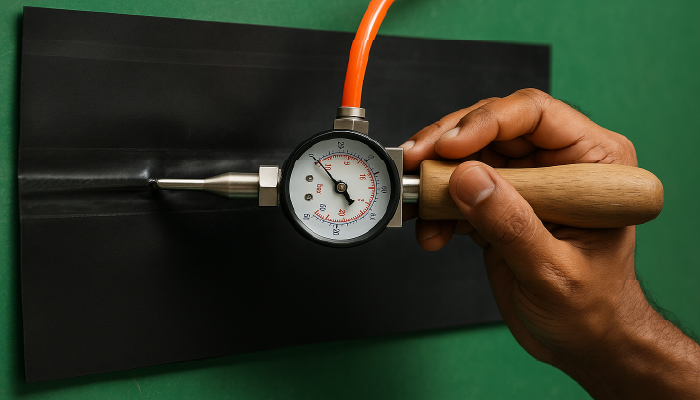

Spark testers are specialized coating inspection equipment designed to detect invisible pinholes, micro-cracks, and coating defects in non-conductive coatings applied over conductive materials such as metal pipelines, tanks, and conductive geomembranes.

How Holiday Detection Works

The spark testing process is straightforward. The device applies high voltage across the coating surface. When the probe passes over any coating defect—no matter how small—it completes an electrical circuit through the conductive substrate, creating a spark and triggering an alarm. This pinhole detection method provides 100% inspection coverage, unlike sampling-based quality control approaches.

The Cost of Undetected Coating Failures

Invisible coating defects lead to serious consequences:

Corrosion and Leakage: In pipeline coatings and tank linings, even pinhole-sized defects allow moisture penetration, initiating corrosion beneath the protective coating that spreads over time.

Product Contamination: Chemical storage tanks and water treatment systems experience contamination or environmental seepage when coating integrity fails.

Expensive Rework: Discovering coating defects after commissioning results in costly shutdowns, system removal, recoating, and warranty claims—often exceeding original project costs.

Project Delays: Post-installation failures cause significant delays while problems are diagnosed and corrected.

Holiday detection through spark testing identifies these problems immediately after coating application, ensuring defect-free protective coatings before system commissioning.

Critical Applications for AC Spark Testers and DC Holiday Detectors

Industries Requiring Coating Quality Inspection

Pipeline Construction: External protective coatings on steel pipelines must be defect-free. Spark testing equipment provides reliable pipeline coating inspection across kilometers of installation.

Petrochemical and Chemical Industries: Tank lining inspection, vessel coating verification, and process equipment require perfect barrier protection against chemical attack.

Plastic Fabrication: Welded plastic joints and seams need coating inspection to ensure leak-proof performance.

Waterproofing Systems: Roof membranes and waterproof coatings require holiday detection to prevent water ingress and structural damage.

Geomembrane Testing: Reservoir liners, pond containment, landfill liners, and waste containment systems need specialized geomembrane integrity testing.

Any industry using non-conductive protective coatings over conductive substrates benefits from implementing spark testing in their quality assurance process.

International Standards for Holiday Detection

While India lacks universal national coating inspection standards, spark testing aligns with internationally recognized protocols widely adopted by Indian EPC contractors and quality consultants:

ASTM D5162: Standard practice for pipeline coating inspection and holiday detection

ASTM G62: Test methods for pinhole detection in non-conductive coatings

NACE SP0274 / SP0188 / SP0490: Guidelines for protective coating testing and geomembrane inspection

ISO 21809-2: External coatings for buried or submerged pipeline systems

These coating inspection standards are pre-programmed into Buckleys spark testing equipment, ensuring compliance with global quality benchmarks.

Buckleys Spark Tester Range for India

At Durel International, we offer the complete Buckleys portfolio of AC spark testers, DC holiday detectors, and geomembrane testing equipment for coating quality control across diverse applications.

Buckleys PST 100: The Most Popular Coating Inspection Solution

At Durel International, we offer the complete Buckleys portfolio of AC spark testers, DC holiday detectors, and geomembrane testing equipment for coating quality control across diverse applications.

Buckleys PHD Pro 2: The Most Popular Coating Inspection Solution

The Buckleys PHD Pro 2 has become our most requested spark testing equipment among Indian clients. This AC spark tester combines reliability, ease of operation, and versatility for pipeline coating inspection, tank lining testing, and general protective coating verification.

Buckleys GeoPro 2: Specialized Geomembrane Holiday Detector

For geomembrane integrity testing—including pond liners, reservoir containment, and landfill systems—the Buckleys GeoPro 2 DC holiday detector provides specialized pinhole detection capabilities designed specifically for geomembrane quality control.

Both coating inspection devices come pre-programmed with international testing standards for immediate compliance and quality documentation.

Breaking Barriers to Spark Testing Adoption in India

Despite proven effectiveness, spark testing equipment adoption in India faces two primary barriers: cost perception and awareness.

Addressing the Investment Question

Many project teams view spark testing equipment as an expensive addition. Consider the reality: a spark tester represents a one-time capital investment used across hundreds of coating projects. Compare this to a single coating failure with repair costs, project delays, warranty claims, and safety incidents—the economics favor quality control investment.

The question isn't whether you can afford coating inspection equipment. It's whether you can afford coating failures.

Simple Implementation and Fast Results

Training: Most operators master spark testing equipment operation in approximately one day of hands-on training.

Testing Speed: Comprehensive coating inspection takes approximately 2 hours per 1,000 square meters—a minimal time investment for defect-free protective coatings.

Workflow Integration: Holiday detection fits naturally after coating application. Test immediately, identify defects, repair while coating crews are on-site, and re-test for verification.

The Competitive Advantage of Quality Assurance

Indian construction, infrastructure, and manufacturing sectors are evolving. Quality standards are rising, project complexities increasing, and failure costs—both financial and reputational—are higher than ever.

What Spark Testing Delivers

Prevention Over Correction: Detect coating defects during installation, not after commissioning. Immediate pinhole detection is always more cost-effective than post-failure remediation.

Documentation and Compliance: Generate verifiable coating inspection records demonstrating quality compliance. This documentation proves valuable during inspections, project handovers, and warranty periods.

Professional Credibility: Organizations implementing comprehensive coating quality control, including spark testing, differentiate themselves as quality-focused partners. This reputation advantage translates into better project opportunities.

Long-Term Performance: Protective coating systems installed with proper holiday detection perform as designed throughout their service life, reducing maintenance costs and enhancing reliability.

Getting Started with Coating Inspection Equipment

If you're implementing spark testing in your coating quality control operations, Durel International provides complete support beyond equipment supply.

Our Partnership Approach

Application Assessment: We evaluate your specific pipeline coating, tank lining, or geomembrane applications to recommend the optimal spark testing solution—whether AC spark testers or DC holiday detectors.

Training and Technical Support: We ensure your team achieves full confidence operating coating inspection equipment according to international standards.

Quality Procedure Development: We help establish holiday detection procedures aligned with ASTM, NACE, and ISO standards for comprehensive quality documentation.

Ongoing Partnership: Continued technical support as your coating inspection program matures and expands.

The complete Buckleys range of spark testers and holiday detectors is available through Durel International, backed by our coating quality expertise and commitment to supporting quality-focused organizations across India.

Why Coating Quality Control Matters

Spark testing provides straightforward, proven technology that eliminates guesswork from protective coating verification. While coating inspection adoption in India continues growing, forward-thinking organizations recognize that comprehensive quality control isn't an expense—it's an investment in reliability, reputation, and long-term success.

Invisible coating defects you can't see today become visible failures impacting your projects tomorrow. Holiday detection gives you confidence that protective coatings meeting visual standards also meet performance standards.

The Path Forward

Prevention is always more cost-effective than correction. Implementing spark testing for pipeline coatings, tank linings, and geomembrane systems protects your investment, reputation, and client relationships.

Organizations serious about coating quality control distinguish themselves in increasingly competitive markets. Proper holiday detection and pinhole testing demonstrate commitment to excellence that clients recognize and value.

Ready to implement spark testing in your coating quality control process?

Contact Durel International to discuss your pipeline coating inspection, tank lining testing, or geomembrane quality control needs. Discover how Buckleys spark testers and holiday detectors can help you deliver defect-free protective coating systems.