Strategic Guidance for Plastic Fabrication Success

Choosing the right equipment is just one part of building successful plastic fabrication capability. Durel International's Expert Consultation Services provide strategic guidance backed by 25 years of plastic welding technology experience to help you make informed decisions that drive measurable business results.

Consultation Investment

Our expert consultation fee of ₹10,000 is completely absorbed as a discount when you proceed with equipment purchase through Durel—making the consultation effectively complimentary for clients who move forward with our recommendations.

Three Core Consultation Areas

1. Figuring Out the Right Product + Material Selection

We evaluate your needs through comprehensive cost of ownership analysis—not just purchase price, but total lifecycle costs including energy, maintenance, repairs, and productivity factors. This ensures equipment delivers acceptable ROI for your business model.

Our recommendations consider material compatibility, production volumes, workflow efficiency, and future growth needs. Using globally renowned equipment brands also brings credibility to your fabrication business, helping you win better projects and command premium pricing.

Real Success Story: We recommended sheet welding equipment to a client using extrusion welders for large-format fabrication. The switch reduced joint count dramatically and increased productivity by 5 times—a recommendation that paid for itself quickly and continues delivering value.

2. Improving Quality Control Processes

Many fabricators lack systematic quality control, relying solely on visual inspection. We help you implement proper testing protocols and equipment integration.

For example, leakages in tanks might not show during hydro testing but create problems in actual service. Implementing spark testing during factory fabrication identifies coating defects before they reach customers, reducing complaints and warranty claims.

We guide you on:

When spark testing is essential for coating applications

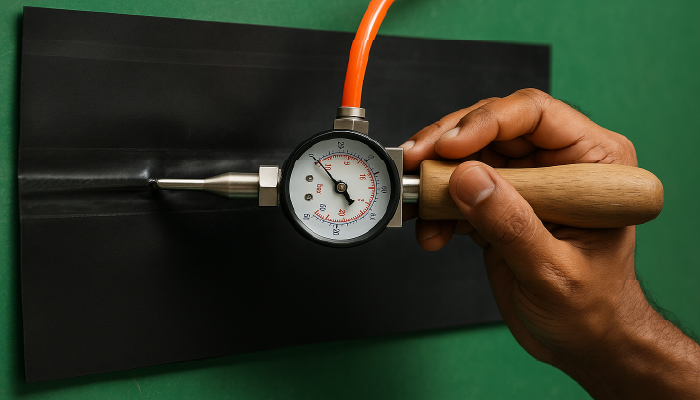

How air pressure testing verifies geomembrane weld integrity

Which inspection methods suit different materials

Documentation systems for traceability and continuous improvement

Quality control isn't just catching defects—it's building processes that prevent them from occurring.

3. Shifting from Metal to Plastic Fabrication

Industries like chemical & pharmaceutical and surface treatment are increasingly adopting plastic fabrication. We help businesses navigate this transition successfully.

Key Benefits We Help You Realize:

Corrosion resistance: Eliminates degradation that destroys metal systems

Weight reduction: Simplifies transportation and installation

Cost efficiency: Better lifecycle costs when accounting for maintenance and longevity

Extended lifespan: Decades